My 83-year-old father has had a lifelong love of woodworking. His career was as a mechanical engineer, but he retired early to pursue his passion for woodworking. And, over the years, that passion has manifested itself in the thousands of wood carvings, pieces of furniture, and entire buildings he created.

I’ve tried to follow in my father’ footsteps in many ways, but I have never shared his love for wood. And, while I would protest to him that wood warps, splinters, and is imprecise, its characteristics are the very essence of his love for it. It was once a living entity and is a natural resource, he would always say, and its beauty lies in its imperfection.

I prefer mechanical things, and since my dad was a mechanical engineer, well, in those footsteps was where I chose to follow. “Mechanical” is, in fact, the very heart of my love of motorcycles. Their parts and pieces, how they fit together, and how they look when assembled are far more beautiful to me than anything made of wood.

However, within this love of mechanical things lies one thing that I absolutely despise with every fiber of my being: the so-called “Phillips-head” screw.

Who was this “Phillips” person, why did he invent Phillips screws, and why on Earth were these diabolical fasteners allowed to propagate?

As it turns out, “Phillips-head” screws were actually created by John P. Thompson, who, after failing to interest manufacturers, sold his design to businessman Henry F. Phillips. Phillips is credited with creating the Phillips Screw Company and promoting his product. Nice going, Henry F. Phillips. I have an idea what the “F” stands for in your middle name.

Slotted screws are bad enough, but with the right-size flathead screwdriver, they work fairly well on installation and removal. But, have you ever, even once, been able to install or remove a Phillips screw without difficulty, emotional distress, and disfigurement of the very fastener you were trying to install or remove? Show me a Phillips-head screw whose head isn’t deformed, chewed up, or hideously burred, and I will assert that that Phillips screw has been heretofore untouched by human hand tools.

I’ve been emotionally scarred for life by my beloved 1975 Yamaha RD350B and, in particular, by the first time I removed the generator cover to check the ignition points when I was 16 years old. Three of what I thought at the time were Phillips-head screws held it in place. One firm twist of the screwdriver on each of those screws, and they didn’t loosen with any kind of elegance. What happened was that the Phillips screwdriver in my RD’s toolkit slipped out of the slots in every one of those three fasteners. I finally managed to remove the three screws, clean the points beneath the cover with a business card, and reinstall the cover and the three screws. I got the job done but those three screws looked like they were attacked by a rabid cold chisel, and they got progressively worse every time I checked or serviced those points.

After several years, I was finally enlightened. I don’t remember when it happened exactly, but I should have because the day I discovered socket-head fasteners (“Allen” bolts) was as momentous and life-changing as the day I got married and the day that my son was born. Beautiful bolts and screws with hex-shaped recesses in their heads, into which you insert a perfect-sized tool, and the fasteners install and remove with absolute precision. The heads remain perfect and ready for multiple removals and installations.

The “Phillips” guy was an idiot, but that “Allen” dude was a genius. In my mind, he is the patron saint of mechanical perfection.

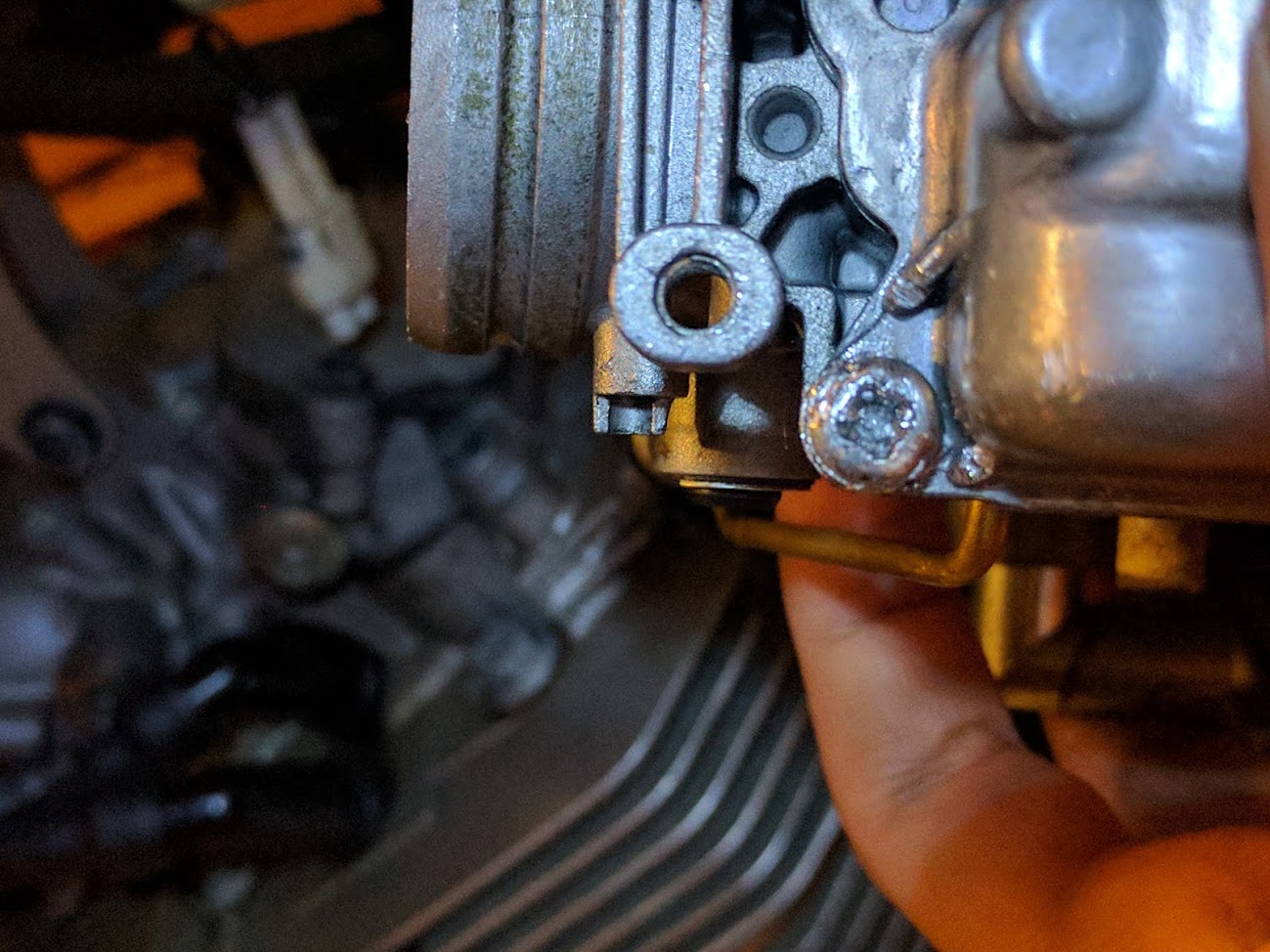

Needless to say, all the serviceable parts and assemblies on my 1975 RD350B—those that are accessible by covers once held on by Phillips-head fasteners—have long been supplanted by glorious socket-head fasteners holding them in place.

In recent years, I discovered that Phillips-head screws were actually designed to fail. They were originally created to assemble aluminum aircraft and prevent overtightening the fasteners. Did I mention the Phillips guy was an idiot?

I also discovered that my motorcycles are assembled with JIS screws, which only resemble Phillips-head screws but have narrower and more vertical slots that reduce the driver’s tendency to “cam out.” By the way, cam out is an actual technical term for the process by which a screwdriver slips out of the head of a screw being driven once the torque required to turn the screw exceeds a certain amount. So, yeah, they even have a name for when Phillips-head screws fail. Hey, Henry F. Phillips, screw you.

In JIS screws, the bottom of the recess is flat, so you have to use JIS-specific screwdrivers to remove and install JIS screws. Also, JIS screw heads are identified by a single dot on one side of the cross slots.

For the record, I have no idea if the screwdriver in my RD350B’s OEM toolkit is JIS-specific or not, but I can tell you that it didn’t remove those three generator-cover screws without severely mangling them. Phillips screwdriver or JIS screwdriver; it didn’t matter. Those screws were FUBAR.

One thing I also discovered in recent years is the variety of socket-head fasteners that are available. Tapered-head sockets. Buttonhead sockets. Titanium. Aluminum. Stainless steel. Chrome, even. And I have happily used them all on my motorcycles.

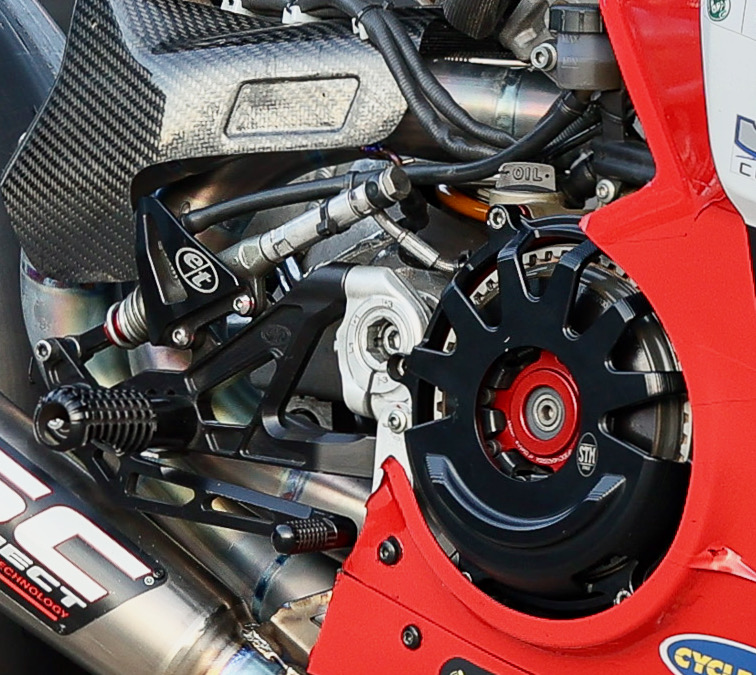

The MotoAmerica paddock is thankfully a fastener nirvana. When I walk through it, I see Allen bolts everywhere. And nary a Phillips-head screw to spoil my day, and pretty much everyone else’s day for that matter.

To purchase tickets for all MotoAmerica events, click HERE

For information on how to watch the MotoAmerica Series, click HERE

For the full 2021 MotoAmerica Series schedule, click HERE